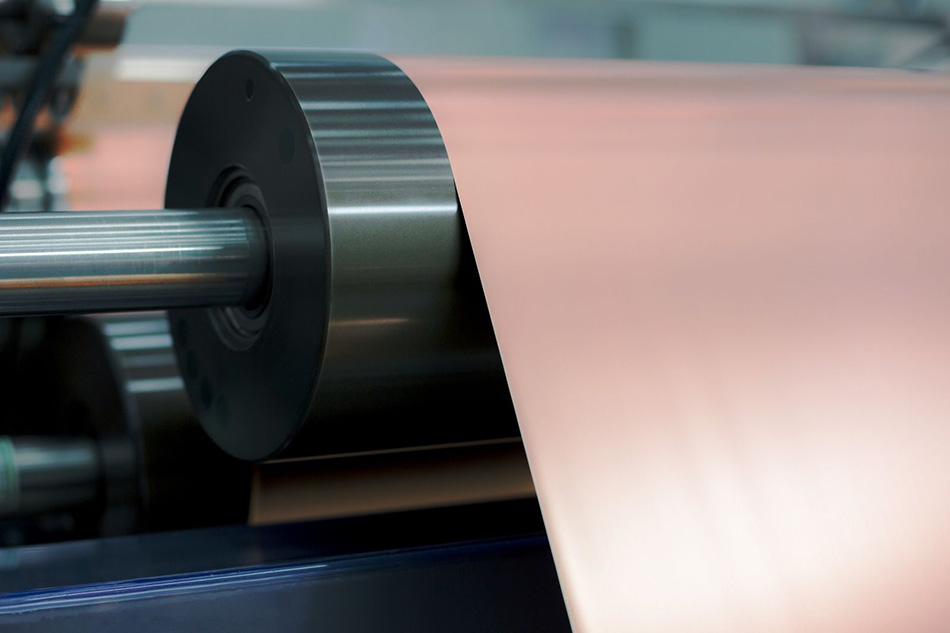

Ngwurugwu ọla kọpa di ala (VLP-SP / B)

Mpempe akwụkwọ micron micron mepere emepe na-abawanye mpaghara elu na-enweghị ihe ike, nke na-enye aka karịsịa maka ịbawanye ike na-abawanye ike. Site na adhesion dị elu, enweghị nchegbu nke irighiri ihe na-ada ada na lines. Uru Rzjis mgbe a na-edobe ya na 1.0 μm na nghọta nke ihe nkiri mgbe a ga-emecha.

●Ọkpụrụkpụ: 12UM 40UM 35UM 50UM 70UM

●Obulọ Ahịa "1290mm, obosara dị obosara: 200-1340mm, nwere ike ịkpụ ya dị ka arịrịọ nha.

●Ngwugwu igbe osisi

●ID: 76 mm, 152 mm

●Ogologo: Khazi aha

●Nlele nwere ike inye

Fool na-emeso ya pink ma ọ bụ ojii na-acha uhie uhie na-acha uhie uhie foil dị ala. E jiri ya tụnyere oge niile elektrik na-eme ka ihe dị mma. Ngwaahịa a barakwa uru ugboro ole na ihe ndị dị elu, ọkachasị bọọdụ sekiiti, bọọdụ chiki dị elu, na bọọdụ chiri anya.

●Profaịlụ dị ala

●Akwa mit

●Ezigbo otch

●2layer 3layer FPC

●Emi

●Sygwọ Goodit Circiti

●Ekwentị mkpanaka ekwentị ikuku

●Ndị isi oche dị elu

| Nke nkewasi | Unit | Iheachoro | Usoro nnwale | |||||

| Notinal Nout | Um | 12 | 18 | 35 | 50 | 70 | Ipc-4562A | |

| Ibu ibu | g / m² | 107 ± 5 | 153 ± 7 | 285 ± 10 | 435 ± 15 | 585 ± | IPC-TM-650 2.2.2 | |

| Nko | % | ≥99.8 | IPC-TM-650 2.3.15 | |||||

| ike ike | Akụkụ na-egbu maramara (RA) | m | ≤0.43 | IPC-TM-650 2.3.17 | ||||

| Akụkụ matte (rz) | um | ≤3.0 | ≤3.0 | ≤3.0 | ≤3.0 | ≤3.0 | ||

| Ike ọdụdọ | RT (23 Celsius C) | Anamba | ≥300 | IPC-TM-650 2.4.18 | ||||

| HT (180 Celsius C) | ≥180 | |||||||

| Elongation | RT (23 Celsius C) | % | ≥5 | ≥6 | ≥8 | ≥10 | ≥10 | IPC-TM-650 2.4.18 |

| HT (180 Celsius C | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 | |||

| Peeji ike (FR-4) | N / mm | ≥0.8 | ≥0.8 | ≥1.0 | ≥1.2 | ≥1.4 | IPC-TM-650 2.4.8 | |

| lbs / na | ≥4.6 | ≥4.6 | ≥5.7 | ≥6.8 | ≥8.0 | |||

| PINLESS & PomaSosis | Nọmba | No | IPC-TM-650 2.1.2 | |||||

| Ahuhu nzu-oidid | RT (23 Celsius C) | Dotutu | 180 | |||||

| HT (200 Celsius C) | Keotiti | 30 | / | |||||